Imikhiqizo

Imikhiqizo emisha

Imikhiqizo

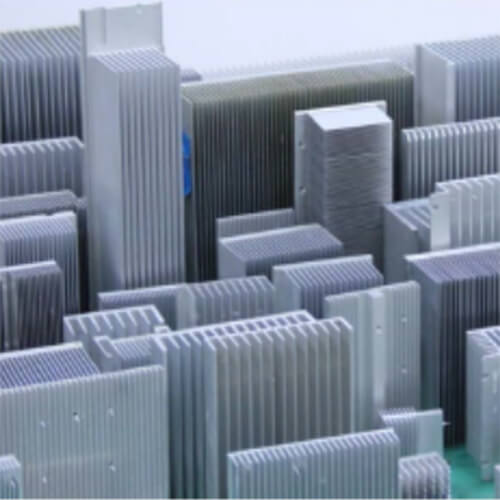

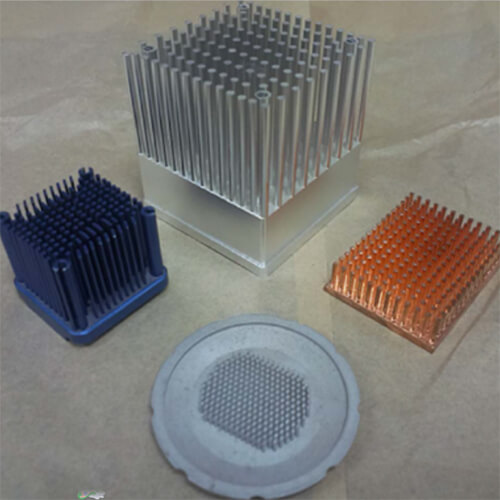

Izici ze-radiator yesithando somlilo kuzoba i-aluminium ingot ngemuva kokushisa okuphezulu okushisa okukhipha induku ye-aluminium, bese kuthi induku ye-aluminium ifakwe ku-groove mold, yenza umbungu we-radiator, bese ngemuva kokucubungula (i-CNC, ukusika, ukubhola, ukuthepha, ukupholisha, ukudweba ngocingo, ukwelashwa ngaphezulu, i-riveting PIN, ukupakisha, njll.)

Funda kabanziThumela UphenyoUkushisa okushisayo kwe-aluminium alloy okuhle kakhulu kuthambile futhi kulula ukucubungula, izindleko eziphansi, ezisetshenziswa kakhulu ekushiseni ukushisa kwanamuhla kwezinto ezinhle kakhulu zokushisa ukushisa, iningi lomkhakha lisebenzisa i-6063 T5 ephezulu ye-aluminium, ubumsulwa bayo bungafinyelela ngaphezu 98%.

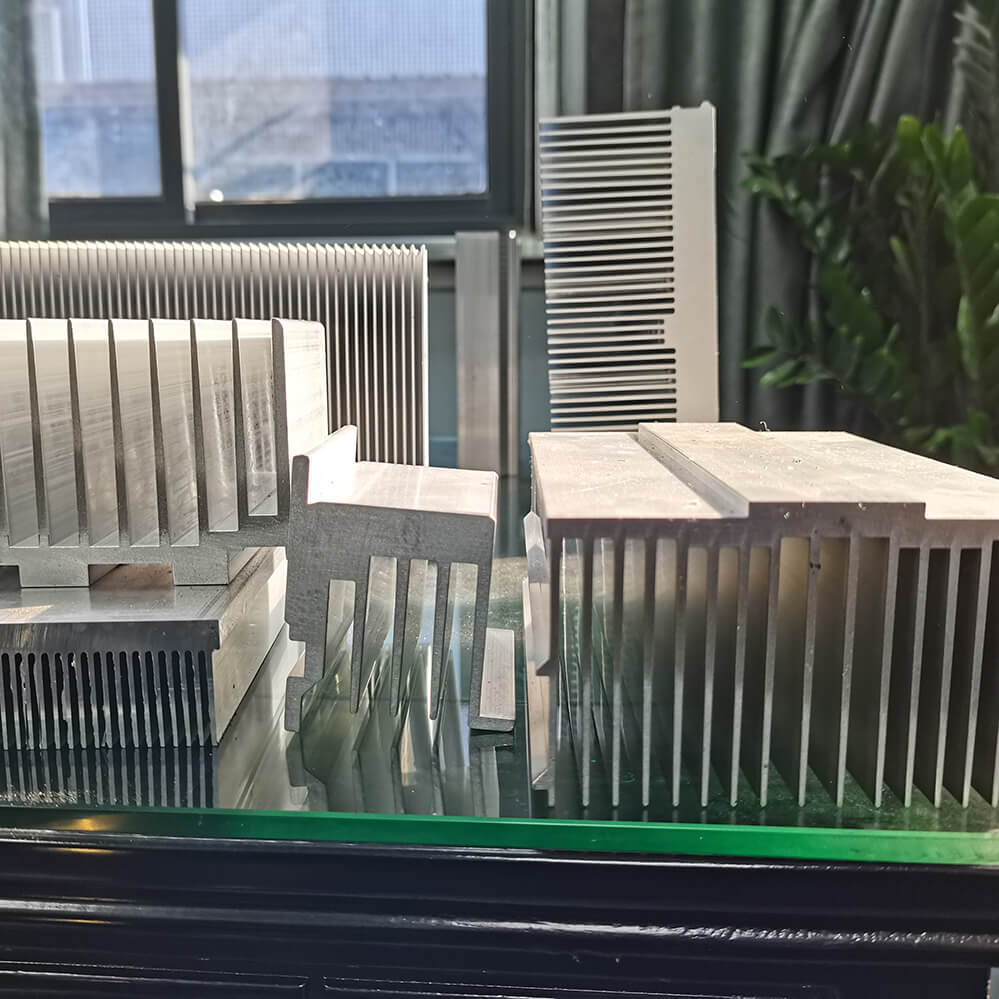

Funda kabanziThumela UphenyoIzinzuzo zidabula imboni ye-aluminium extrusion ekuphakameni kokushisa kwe-blade blade nobukhulu besakhiwo esiningi noma esiyinkimbinkimbi semikhawulo ye-blade, ingaveza i-radiator ephakeme kakhulu, ingakhetha izinto ezihlukile ze-blade, futhi ukusebenza kahle komkhiqizo kuphezulu, izindleko zomkhiqizo phansi

Funda kabanziThumela Uphenyoukungalungi kwezindleko zokucindezela ukushisa kwamazinyo okufosholo kuphakeme, futhi imfucuza eyenziwe, futhi kunesilinganiso esithile sokwehluleka, lapho ifosholo liyirejitha ende kakhulu, sonke isikhawu sobude obungu-150mm sizoba ne-4mm noma ngaphezulu.

Funda kabanziThumela Uphenyo